AND NOW... Compliance testing using EPA New protocols and the testo 350 is faster and less costly than ever before.

EPA’s new testing protocol, combined with the testo 350, is shaking up the compliance testing world by saving testers time and money. It’s been known for decades that testing protocols for Electrochemical (EC) based analyzers did not utilize the benefits of the sensing technology. A better test method was needed, and now it’s here. The performance test method OTM 39 can be downloaded from EPA website (https://www.epa.gov/sites/production/files/2020-08/documents/otm-39_performance_method_using_portable_gas_analyzers_08_24_2020.pdf)

For More information on the periodic monitoring OTM 38, go the main page here - https://www.epa.gov/emc/emc-other-test-methods#Other%20Test%20Methods

Measurement accuracy of the testo 350 was proven long ago, but the bureaucracy did not allow the benefits of Testo’s sensors to be utilized. Testers were saddled with calibration procedures that did little to assure accuracy and consumed large quantities of expensive calibration gas. It all changed with the issuance of the New Protocols (OTM 39 for performance testing, OTM 38 for Emission checks.

Using the testo 350, along with the TECsoft compliance software will make you testing faster, less costly, and more successful.

The Control Unit controls the analyzer box and displays the measurements in a high definition graphic display. View the separate values or the trending graphs. Select the “Rich Burn” or Lean Burn” engine icon and the analyzer will activate the proper settings and guide you through the measurement. Save each reading or let the automatic program data log the test.

One test run or three? You define it or use one of the default programs (i.e. EPA CTM-034). Bluetooth connectivity to over 330 feet keeps your informed of the readings. The Control Unit’s magnets allow you to dock next to the AFR cabinet which makes for easier combustion adjustments. You can also connect via USB to stream data seamlessly.

The Analyzer Box (contains the sensors, pumps, power, etc.) The 300-foot Bluetooth connection allows the analyzer to be closer to the stack, and you in a better location. The closer location results in sensor response times faster than any other portable analyzer in the market. The 350 uses a patented sample gas path and advanced Peltier sample conditioning system. The chiller is temperature monitored and controlled and continuously removes moisture from the gas path. It starts with a powerful pump that pulls a high velocity sample through a Teflon sample line all the while monitoring flow rate and automatically adjusting to maintain a constant flow. Perfect for compliance testing. It’s the most advanced and most powerful sample preparation system in the market. It not only satisfies EPA compliance for a dry sample, it also protects the sensors for longer life.

Ideal Features for Engine Testing

- Sensors include: O2 (0-25%), CO (0 -10,000ppm with dilution to 400,000 ppm), NO (0-4000 ppm) and NO2 (0-500 ppm) for a “True NOx” reading. Hardware protections make the sensors last up to 5 years making cost of ownership the best in market. Sensors are plug & play allowing you to change in field to a LOW NOx 0.1 ppm measurement.

- The “RICH burn” mode activates the CO dilution to the 50,000 ppm (5X) range. Switch to a 10X when commissioning for even better sensor protection. Switch to “overall-dilution” to double the range on CO, NO, and NO2. The analyzer will automatically calculate and display the corrected values. User defined setpoints means you can extend sensor life and maintain accurate measurements. Switch to “LEAN burn” mode to deactivate.

- Dilution system allows for more accurate CO measurement throughout the testing range. See our white paper on our Hydrogen compensated CO sensors. It provides the technical reasons the testo 350 has superior accuracy.

- Important displayed values. See the raw NO and NO2 (and NOx) values along with the NOx corrected value to 15% O2 (or other user-defined percentage). This way you can immediately see if you are below, or above your permit limit.

- Calculates and displays grams per brake horsepower hour (g/bhphr.) Just input the fuel consumption and BTU value, horsepower and f-Factor, and the analyzer will calculate the “grams.” It doesn’t get any easier than this.

- Automatic data logging programs – Set up one run or three. Set the time interval and sampling rate. During the run, check the calculated averages NOx and CO reading against your permit limits. Yes, you can watch the status real time. This saves valuable time and allows you to stop a test and adjust the engine instead of wasting time on a failed test.

- Convenient “fresh air” button purges sensors. Press the button to purge instead of climbing ladders to remove the probe. The “purge” increases sensor life, establishes better sensor equilibrium, and virtually eliminate measurement drift.

- Onboard diagnostics helps you before the emissions test! Push the i (information) button to see: sensor, battery, error code, and leak check status.

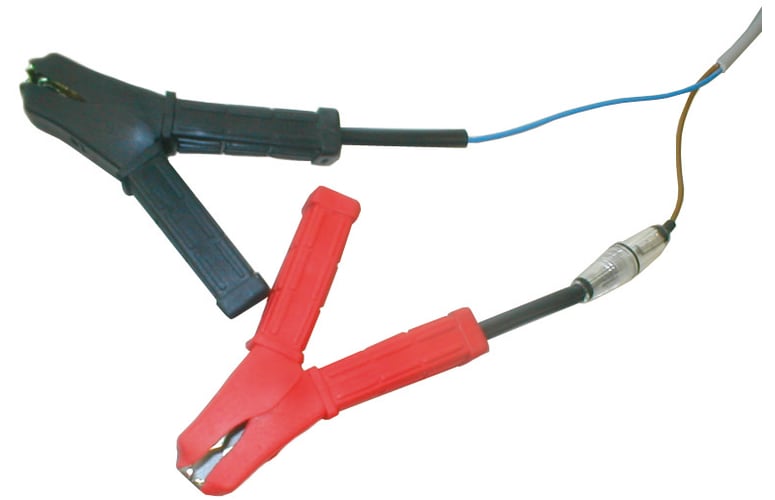

- On-Site Calibration – Even with the best sensors in the market, calibrations are a protocol necessity. Here the testo 350 shines in its simple procedures and intelligent feedback to let you know if you’re having problems. It shows the gas flow rate and even detects and informs you if the concentrations are not correct. The 350 has instrument intelligence that at the highest level.

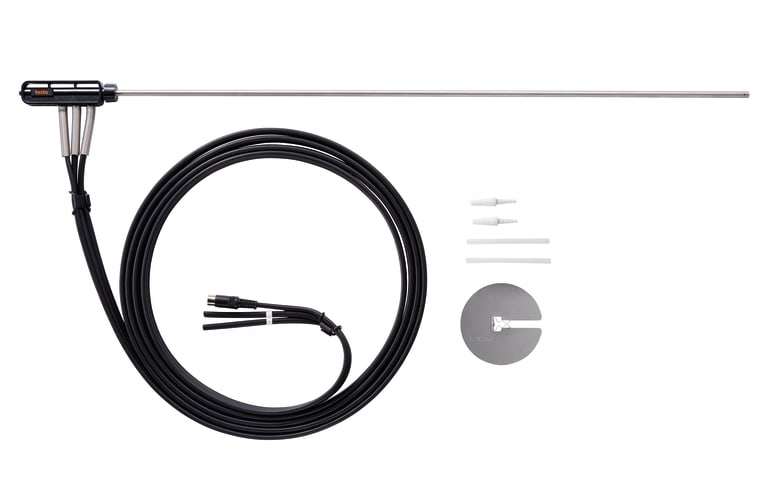

- The Engine Probe utilized high temperature stainless steel, heat deflector shield and cone allow it to be used on hot engine applications. A 13-foot Teflon lined hose and an extra filter/condensate trap protects the analyse from moisture especially when sampling from a drop hose.

Other Useful Options for Engine Testing:

- For Diesel testing – use the sintered filter probe to keep high soot levels from entering probe and analyzer. The welded-on filter withstands high vibration and provided better engine security.

- Hose extensions - 9-foot quick connect extensions means you can extend the hose to 25 feet. Disconnect them for easier, less bulky transport.

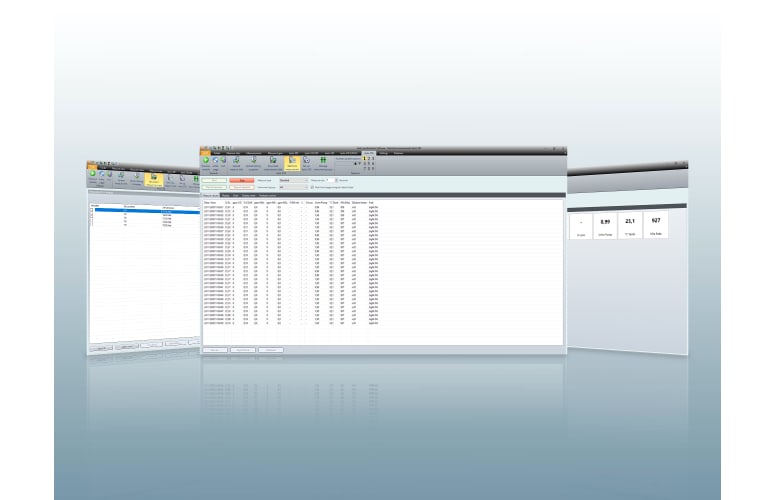

- TECsoft (Testing & Emission Compliance Software) – for real time data logging (or downloading from instrument memory) directly into excel report templates. Eliminates the copy and paste hassles. Pull together the Pre- and Post-calibration gas data for comprehensive reports. Highly flexible and easily customized Excel report templates.

Testo 350 – Probes and hoses - Options

- Probe adapters to attached you own sampling hose via Swagelok fittings

- Heated sample lines (self-regulating), lightweight with small turning radius and with LED features to let you know the heating status

- Industrial sample probes from 3 feet to 9 feet long. Made from stainless steel, Inconel, or Ceramic covers a wide variety of temperature needs. From 1112⁰F to 3200⁰F