- Home

- testo 174 T

testo 174 T - Mini temperature data logger

0572 1560

testo 174 T - Mini temperature data logger

0572 1560Measurement data memory for 16 000 temperature readings, approx. 500 days of battery life

High data integrity, even with an empty battery

Waterproof according to IP 65, HACCP-compliant and certified according to EN 12830

Data analysis: three possible software versions to choose from, basic software available as a free download

You need a USB interface to program and read out the data logger .

Click here to go to the set (testo 174 T + USB interface).

Attention: Please download the newest software version before using the USB interface for the first time. The software can be found in the download area.

testo 174T mini temperature data logger, including wall bracket, batteries (2 x CR 2032 lithium) and calibration protocol.

General technical data

| Weight | 35 g |

|---|---|

| Dimensions | 60 x 38 x 18,5 mm |

| Operating temperature | −30 to 70 °C |

| Product-/housing material | Plastic |

| Protection class | IP65 |

| Channels | 1 internal |

| Product colour | white |

| Standards | EU-guideline 2014/30/EU; 2011/65/EU |

| Measuring rate | 1 min - 24 h |

| Battery type | 2 x 3V button cell (CR 2032) |

| Battery life | 500 days (15 min measuring cycle, +25 °C) |

| Memory | 16.000 measuring values |

| Storage temperature | −40 to +70 °C |

Product sets

Product sets

Measurement data memory for 16 000 temperature readings, approx. 500 days of battery life

:

0572 0561

0572 0561

€ 138,00

€ 168,36Accessories

Accessories

To potrdilo o kalibraciji ISO se uporablja za kalibracijo merilne naprave ali senzorja. Kalibracija je izvedena v skladu s standardom ISO.

:

0520 0153

0520 0153

Accessories

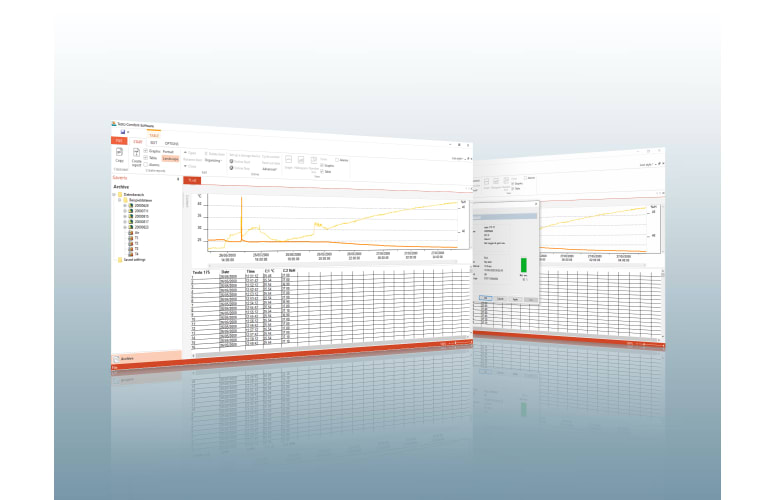

ComSoft Professional software for programming and readout of Testo data loggers and for archiving data

:

0554 1704

0554 1704

€ 386,00

€ 470,92Accessories

USB interface for data loggers

:

0572 0500

0572 0500

€ 101,00

€ 123,22Accessories

Free download: testo ComSoft Basic for programming and reading Testo data loggers

:

0572 0580

0572 0580

Accessories

Lithium battery, button cell, type CR 2032

:

0515 5028

0515 5028

- Data sheet testo 174T(pdf, 273.91 kB)

- EU declaration of conformity testo 174 T(pdf, 33.8 kB)

- Short manual testo 174(pdf, 760.31 kB)

- Instruction manual testo 174(pdf, 1.8 MB)

- Instruction manual testo 174-H. -T(pdf, 1.77 MB)

- Short manual testo 174-H. -T(pdf, 1.94 MB)

- testo usb driver - Instruction manual(pdf, 676.7 kB)

- ComSoft Basic Instruction manual(pdf, 868.78 kB)

- testo usb driver - for various measuring instruments(v2.9.1, 2.02 MB)USB driver for the following devices with USB port: * USB Interface testo 174 / 177 - T + H * testo 300 / 320 / 330 / 330i / 335 / 340 / 350 * testo 435 * testo 556 / 560 / 570 / 580 * testo 635 * testo 735 * testo 845