You can carry out completely non-destructive tests on materials and components in industrial thermography with the testo 875-1i. This allows you to reveal problems in industrial maintenance and production monitoring before a malfunction occurs or fire risks develop. And for good measure, you can create a real image in parallel to the thermal image thanks to the built-in digital camera. This makes documentation and assignment easier for you.

You can detect possible structural defects with the testo 875-1i thermal imager in building thermography. With the excellent thermal sensitivity of < 50 mK, you can quickly and efficiently track down energy losses and so help your customers to save expensive heating costs and plan refurbishments.

In the “Applications” tab, you can find out more about the thermal imager's fields of application.

The testo 875-1i infrared camera’s technical features

The testo 875-1i thermal imager is characterised by its intuitive operation, excellent thermal sensitivity and built-in digital camera. Read all the important information here:- Built-in digital camera: Recording real images in parallel to each thermal image makes documentation and assignment easier

- Resolution and image quality: Detector size 160 × 120 pixels = 19 200 temperature measuring points. SuperResolution Technology enables you to take image quality right up to the next level of 320 × 240 pixels in next to no time. Four times as many readings and a geometric resolution that has been improved by a factor of 1.6 mean you get even more detail and even greater reliability with thermographic measurements

- Thermal sensitivity < 50 mK: Thanks to a temperature resolution of < 50 mK, even the smallest temperature differences can be seen

- High-quality 32° × 23° lens: The lens with its manual focusing enables a wide field of view and an ideal overview of the temperature distribution, along with precise focusing on the object being measured

- Automatic hot/cold spot detection: Critical temperature conditions are directly displayed during thermography

- Solar mode: The solar radiation value can be input into the thermal imager and stored with each thermal image

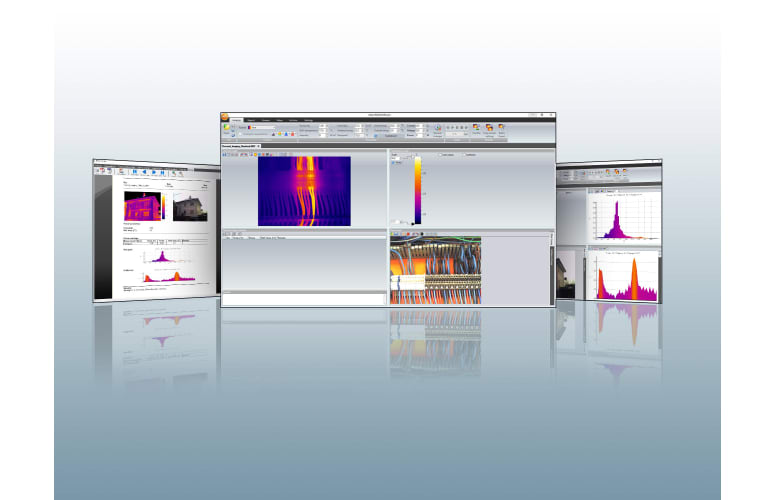

- Pro software for image evaluation on the PC included. You can also choose to save the thermal images as JPEGs. Find out more about the software

- Measuring range: -30 to +350 °C