The Testo 310 basic flue gas analyzer. For reliable heating system checks

Fully featured and priced right, the Testo 310 residential combustion analyzer provides exceptional value and complete capabilities in combustion testing and furnace efficiency. With its capability to perform both basic, or more complex flue gas analysis, maintenance or safety checks, or confirm furnace efficiency, the fully featured Testo 310 combustion analyzer delivers more combustion parameters.The stainless steel probe and cone-stop is perfect for residential, and boiler applications. The 310 can be used for accurate heating adjustments, so you can get it right the first time - every time.

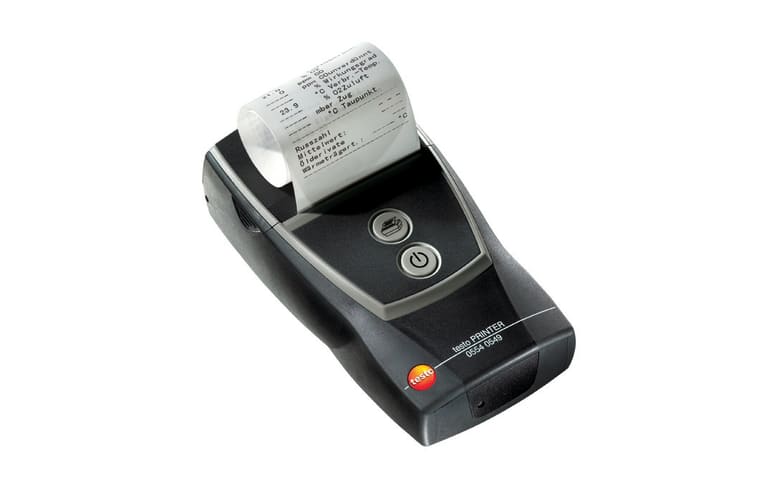

With five different fuels to select from (Natural Gas, Propane, Fuel Oil , Biomass 5%, Wood 20%), it provides the flexibility you need for your tuning opportunities. With an optional printer kit available, you are able to keep records of all readings taken.