The testo 865 thermal imager offers professional technology and concentrates on functions which are needed in a contractor's daily work. The testo 865 is a user-friendly thermal imager, optimized for fast and efficient work. With the testo ScaleAssist functions ensuring optimum setting of the thermal image scale for building thermography and the IFOV warner making sure you avoid measurement errors, you will always generate the perfect infrared image.

Areas of application of the testo 865 thermal imager

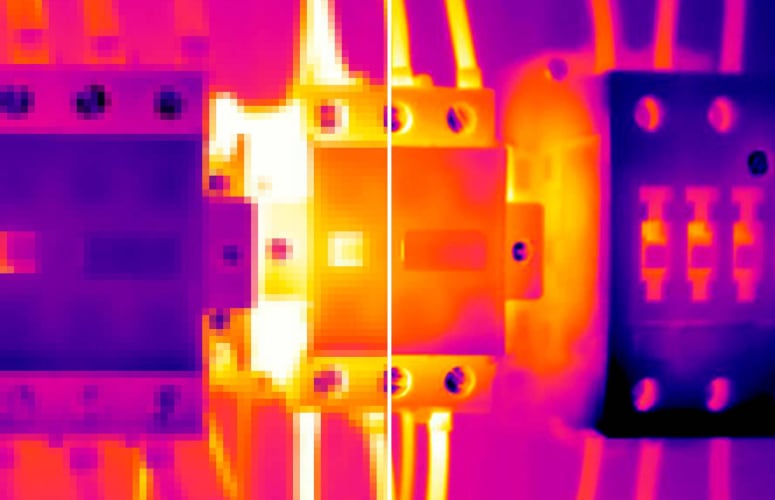

Detect leaks, identify overheated connections, pinpoint thermal bridges or detect structural defects. The testo 865 thermal imager is ideal for applications in daily maintenance and installation work in trade and industry. It enables time-saving quality assurance and ensures reliable production control.

Technical highlights of the testo 865 thermal imager

The testo 865 thermal imager stands out thanks to its easy operation and has the following impressive technical features:

- Very good image quality due to high resolution: 19,200 temperature measuring points ensure precise thermography. Infrared resolution of 160 x 120 pixels – via integrated SuperResolution Technology 320 x 240 pixels

- Visualize temperature differences from 0.1°C

- Critical temperature conditions are directly displayed via automatic hot-cold spot recognition

- The IFOV warner means the distance from the measurement object / measurement spot size is determined and the measurement spot is shown on the thermal image – you therefore avoid measurement errors because the camera shows you exactly what you can measure

- The testo ScaleAssist automatically ensures optimum setting of the thermal image scale, which means you generate objectively comparable and error-free thermal images, for example of the thermal insulation behaviour of buildings

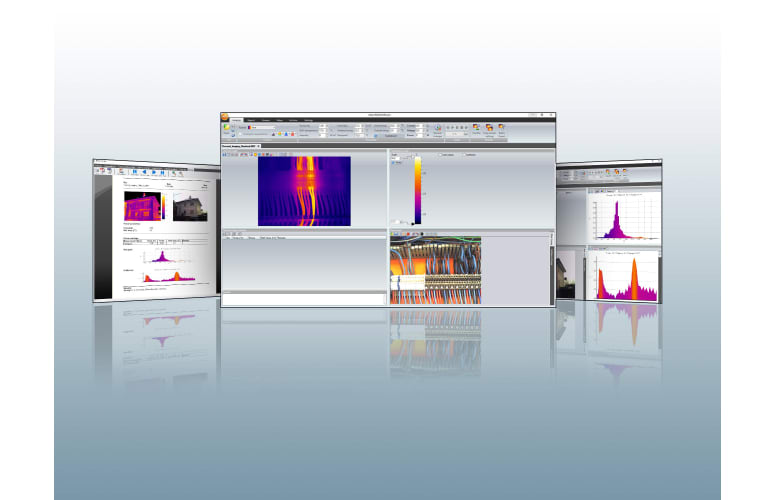

- Pro software for image evaluation on the PC

- You can choose to save thermal images as JPEGs

testo 865 thermal imager, including USB cable, mains unit, lithium-ion rechargeable battery, IRSoft professional software (free download), commissioning instructions, short instructions, calibration protocol and case.