- Home

- testo 174 T starter kit

testo 174 T starter kit

0563 0561

testo 174 T starter kit

0563 0561Measurement data memory for 16,000 temperature readings, approx. 500 days of battery life

In the kit: Three testo 174T mini temperature data loggers, USB interface, wall bracket, batteries and calibration protocol

Waterproof according to IP 65, HACCP-compliant and certified according to EN 12830

Different software variants available for data analysis

Product no longer available. Have you checked out its successor?

Why not enjoy the benefits that it has to offer: >> To the product

Why not enjoy the benefits that it has to offer: >> To the product

- 3 x testo 174T mini data loggers for temperature (0572 1560)

- USB interface (0572 0500)

- Wall bracket

- 2 x Lithium batteries CR2032 (0515 0028)

- Calibration protocol

General technical data

| Weight | 35 g |

|---|---|

| Dimensions | 60 x 38 x 18.5 mm |

| Operating temperature | -30 to 70 °C |

| Product-/housing material | Plastic |

| Protection class | IP65 |

| Channels | 1 internal |

| Product colour | white |

| Standards | EU-guideline 2014/30/EU; 2011/65/EU |

| Measuring rate | 1 min - 24 h |

| Battery type | 2 x 3V button cell (CR 2032) |

| Battery life | 500 days (15 min measuring cycle, +25 °C) |

| Memory | 16,000 measuring values |

| Storage temperature | -40 to +70 °C |

Temperature - NTC

| Measuring range | -30 to +70 °C |

|---|---|

| Accuracy | ±0.5 °C (-30 to +70 °C) |

| Resolution | 0.1 °C |

General technical data

| Product-/housing material | Plastic |

|---|---|

| Product colour | white |

| Weight | 150 g |

General technical data

| System requirements | Windows® 10; Windows® 11 ; others on request |

|---|---|

Product sets

Product sets

Measurement data memory for 16 000 temperature readings, approx. 500 days of battery life

:

0572 0561

0572 0561

SAR 690

Product sets

testo 174 T starter kit

:

0563 0561

0563 0561

SAR 1 209

Accessories

Accessories

ISO calibration certificate temperature

:

0520 0153

0520 0153

Accessories

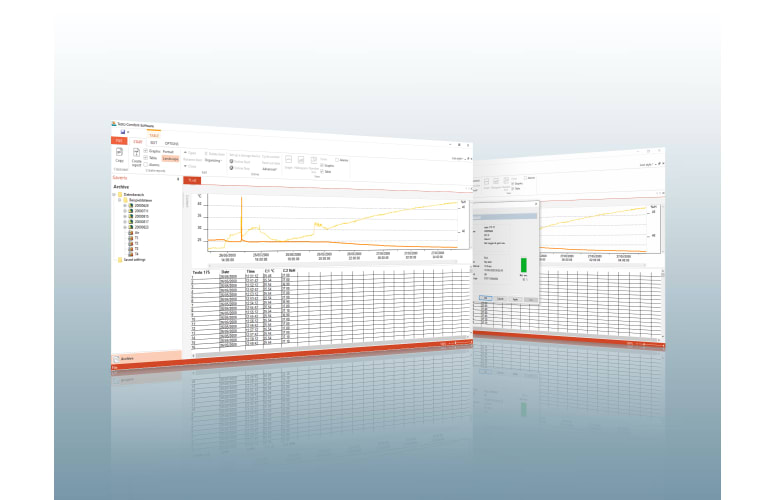

ComSoft Professional software for programming and readout of Testo data loggers and for archiving data

:

0554 1704

0554 1704

SAR 1 929

Accessories

USB interface for data loggers

:

0572 0500

0572 0500

SAR 505

Accessories

Free download: testo ComSoft Basic for programming and reading Testo data loggers

:

0572 0580

0572 0580

Accessories

Lithium battery, button cell, type CR 2032

:

0515 5028

0515 5028

Monitoring and documenting the temperature in cold storage areas

Many foods or medicinal products have to be stored within a specific cold temperature range. This may be in individual refrigerated storage rooms, but also in specialised cold storage warehouses or high bay cold store warehouses. The temperature has to be continuously documented in all of these refrigerated facilities, since strict regulations apply to quality management both in the food and pharmaceutical industries.Data loggers are usually placed at the ‘Critical Control Points’ (CCPs) of a cold storage area to enable any fluctuations in temperature to be detected and appropriate action to be taken. Critical places include doors or passages into other temperature zones within a warehouse.

Monitoring and documentation of transport temperature

During the transportation of food and pharmaceuticals, clearly defined temperature limits must be complied with in most cases - and this needs to be done seamlessly and continuously.

The wrong temperature conditions during transportation can result in major losses in quality or even a complete loss of value for the monitored products.

With the aid of a data logger, goods in transit can be monitored to make sure specified temperature zones are being observed; this can then be read out, analyzed and stored using special software.

Monitoring the temperature in deep-freeze storage areas for food

There are many facilities where (deep) frozen foods need to be stored. These range from individual deep-freeze rooms at small food producers (e.g. butcher's shops), restaurants and supermarkets, via deep-freeze rooms in the food processing industry, right through to specialized refrigerated warehouses/high-bay deep-freeze warehouses. In all of these facilities, the temperature has to be documented continuously. Only temperature recording devices that comply with EN 12830 are allowed to be used in Europe. Data loggers are typically used to measure the air temperature in these kinds of storage facilities. The measuring instrument is positioned within the freezer room at the critical places where possible, such as by doors or refrigeration units, where it records temperature data at specified intervals (typically: every 15 minutes). The recorded data can subsequently be analyzed and archived using special software.

- Data sheet testo 174 T(pdf, 273.91 kB)

- EU declaration of conformity testo 174 T(pdf, 33.8 kB)

- Short manual testo 174(pdf, 760.31 kB)

- Instruction manual testo 174(pdf, 1.8 MB)

- Instruction manual testo 174-H. -T(pdf, 1.77 MB)

- Short manual testo 174-H. -T(pdf, 1.94 MB)

- testo usb driver - Instruction manual(pdf, 676.7 kB)

- ComSoft Basic Instruction manual(pdf, 868.78 kB)

- testo usb driver - for various measuring instruments(v2.9.1, 2.02 MB)USB driver for the following devices with USB port: * USB Interface testo 174 / 177 - T + H * testo 300 / 320 / 330 / 330i / 335 / 340 / 350 * testo 435 * testo 556 / 560 / 570 / 580 * testo 635 * testo 735 * testo 845

- testo usb driver - Instruction manual(pdf, 676.7 kB)

- ComSoft Basic Instruction manual(pdf, 868.78 kB)

- testo usb driver - for various measuring instruments(v2.9.1, 2.02 MB)USB driver for the following devices with USB port: * USB Interface testo 174 / 177 - T + H * testo 300 / 320 / 330 / 330i / 335 / 340 / 350 * testo 435 * testo 556 / 560 / 570 / 580 * testo 635 * testo 735 * testo 845

- ComSoft Basic Instruction manual(pdf, 868.78 kB)