All the important information about the testo 883-1 thermal imager

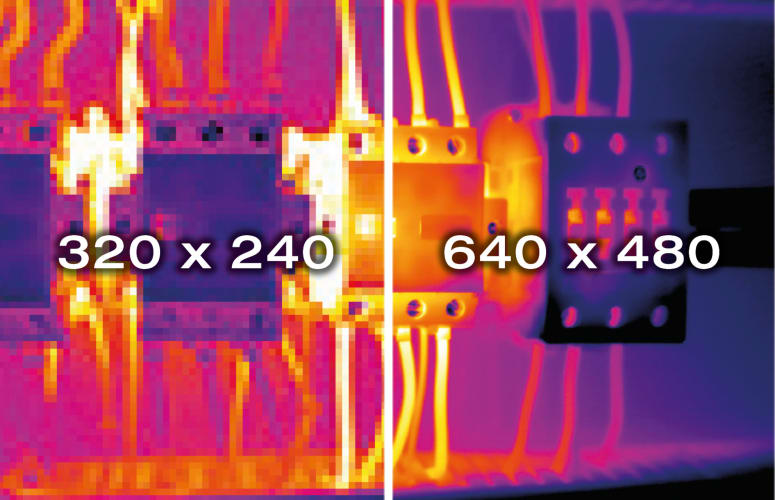

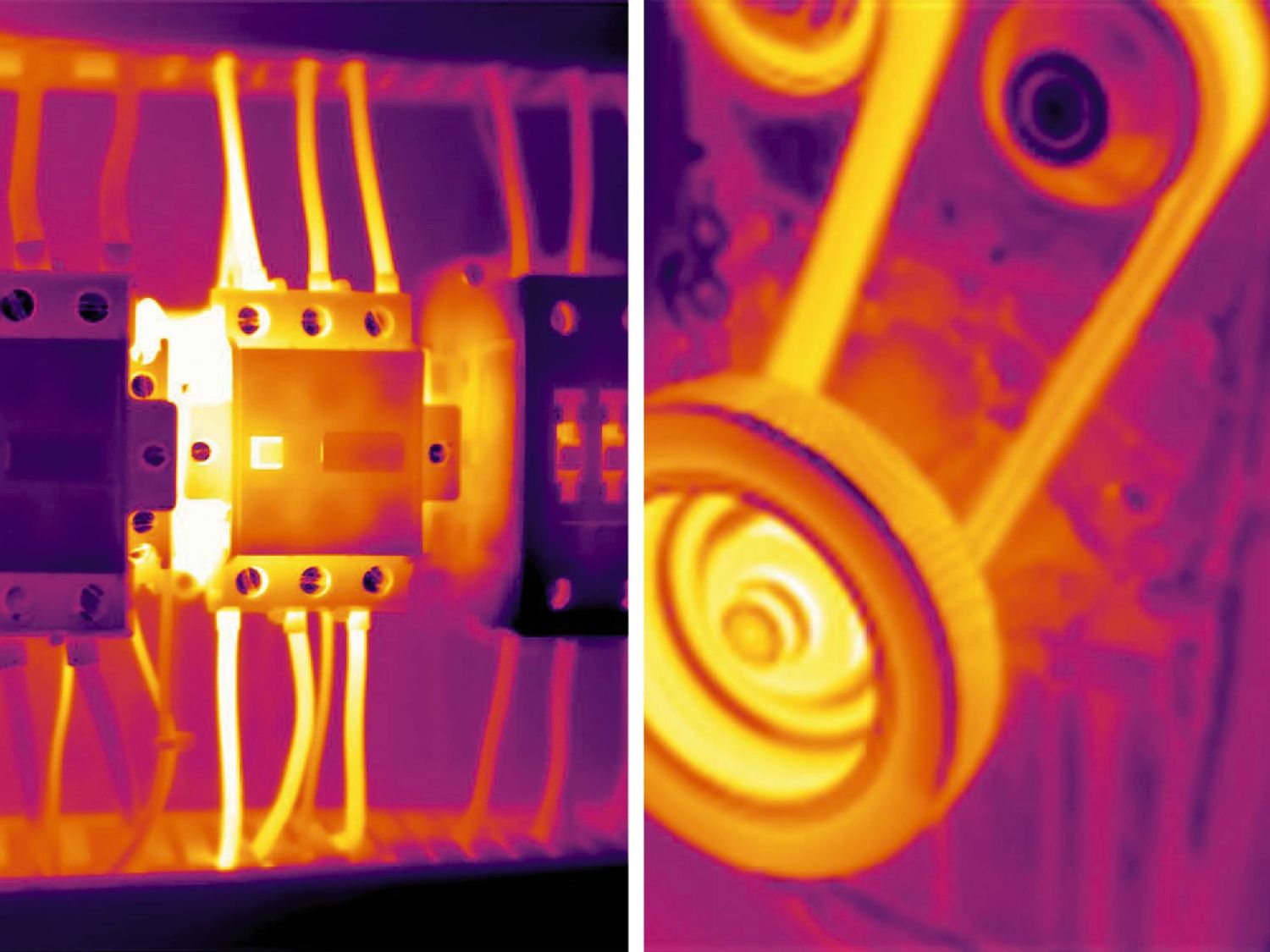

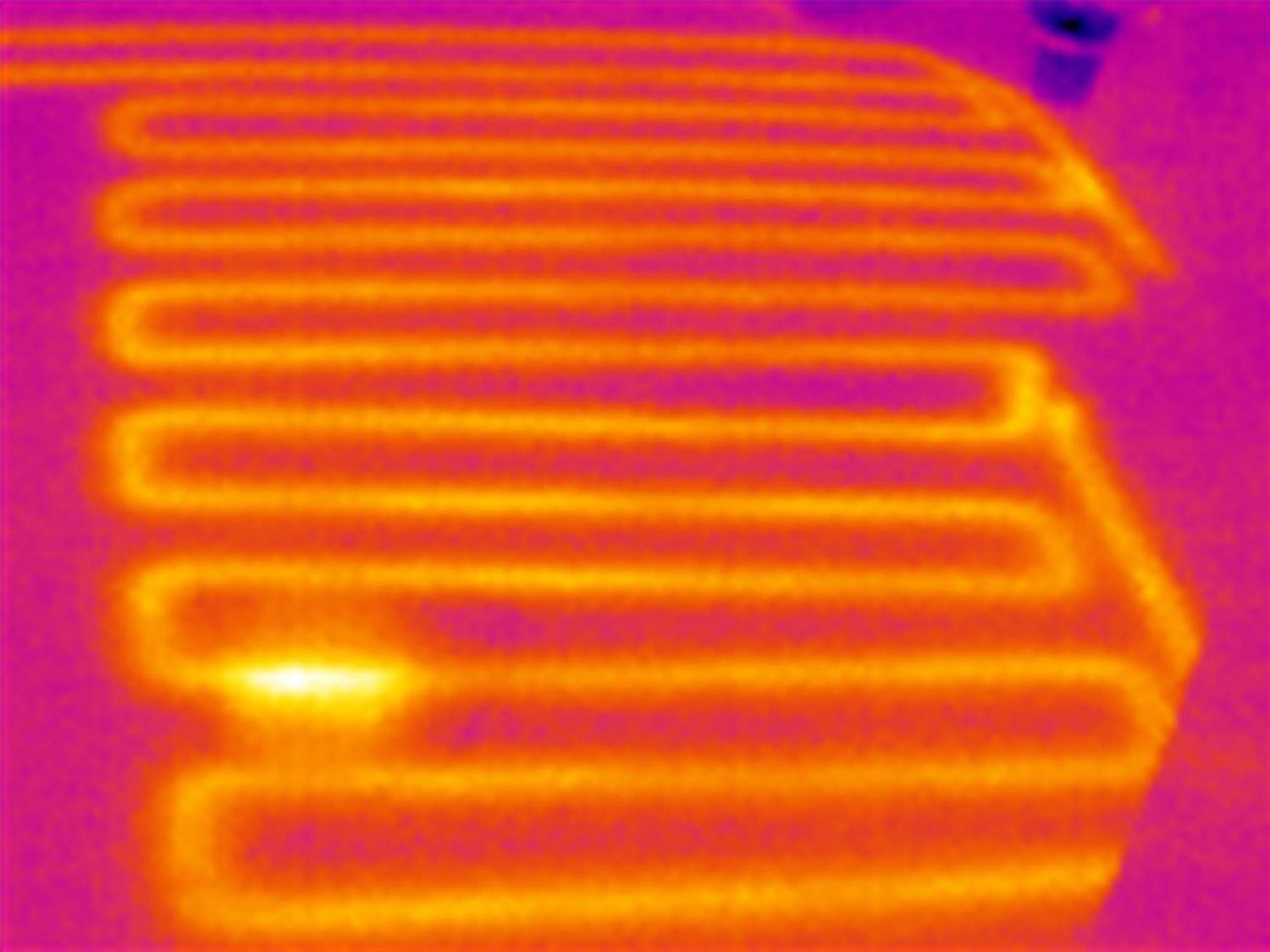

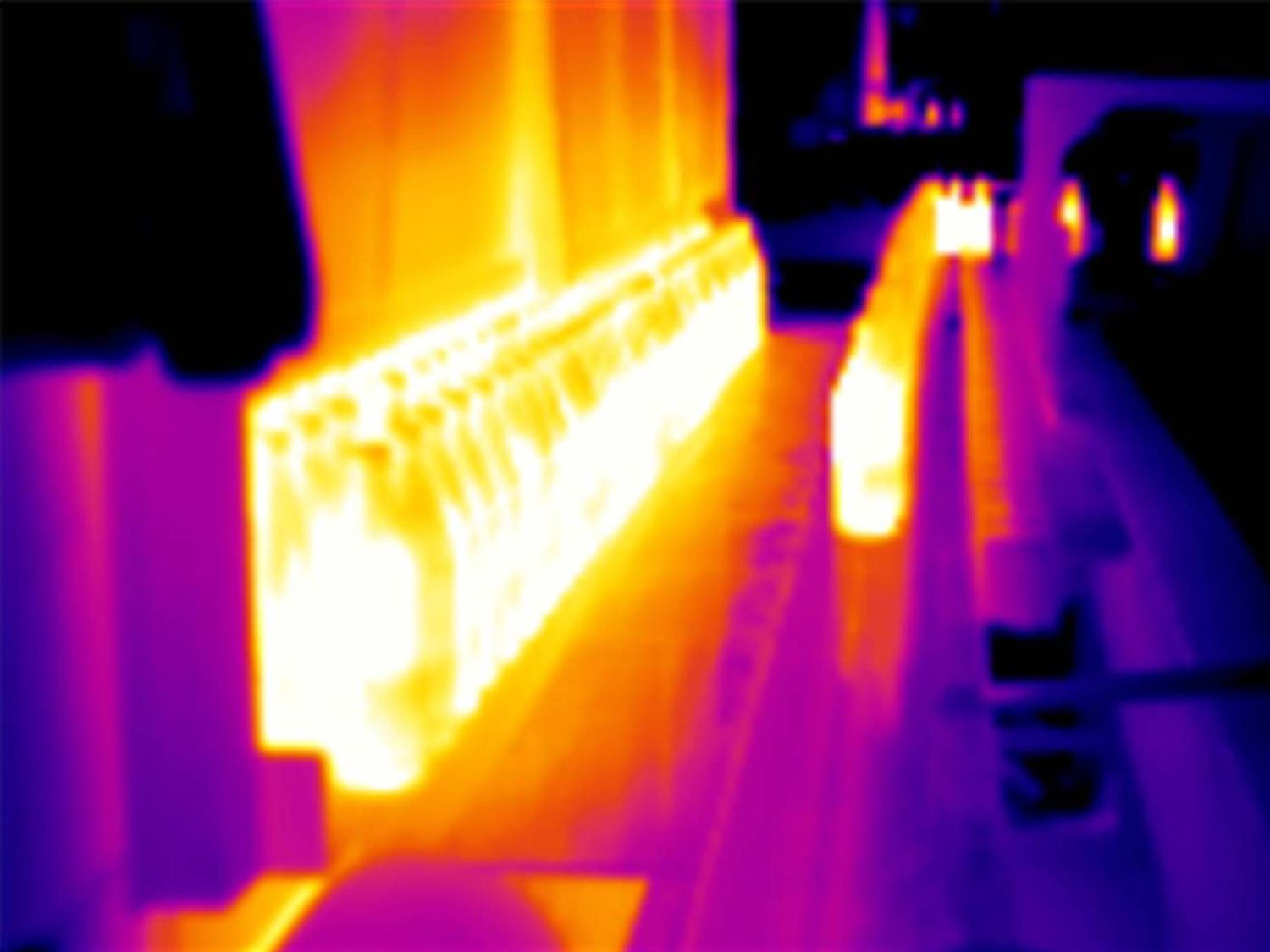

- IR resolution of 320 x 240 pixels (with SuperResolution 640 x 480 pixels), manual focus and a very good NETD of 40 mK all ensure the best image quality – so you can reliably detect thermal abnormalities in installations and buildings

- testo SiteRecognition enables intelligent image management. Thermal images are automatically assigned to the correct measurement object based on the QR code at the measuring location – this eliminates the need for tedious, manual image assignment on the PC

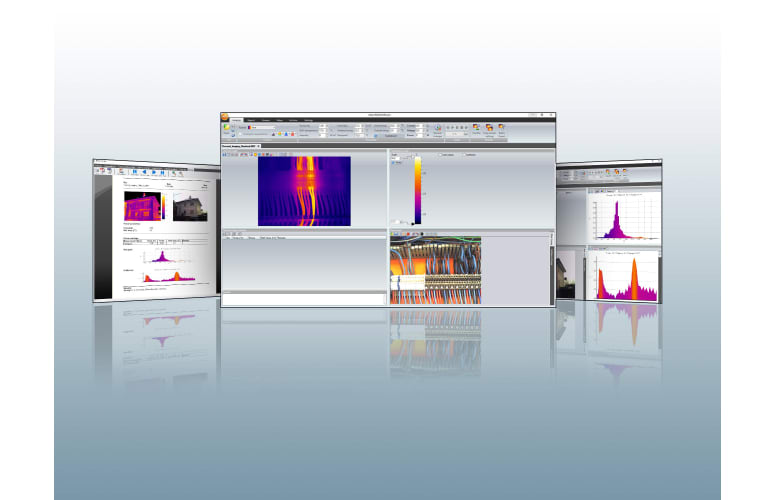

- testo IRSoft: Analyze thermal images comprehensively with the intuitive, professional PC software and create impressive reports within a short period of time

- testo ScaleAssist: Automatic contrast adjustment for objectively comparable thermal images and easier detection of weak spots

- testo Thermography App: With the app, your smartphone/tablet becomes a second display and a remote control for your thermal imager. You can quickly create, send or save reports on site

- Interchangeable telephoto lens for distant objects and outdoor recording

- Manual focus for sharp thermal images from a distance of 10 cm

- Can be operated via touchscreen and joystick

- Wireless transmission of readings from clamp meter or humidity probe directly into the thermal image via Bluetooth®

Further advantages for service engineers and facility managers

- Easy to handle – clever management of images and data thanks to testo SiteRecognition: automatic assignment of thermal images to the correct measurement object using QR code, Data Matrix code, barcode or Testo 2D code, transfer of measuring locations from existing inventory lists, export of work results (in .xls format) enables further processing in third-party programs

- Smart: Carry out quick analyses directly on site with the testo Thermography App and share thermal images with colleagues straight away

- Networked: Wireless transmission of readings from the Testo clamp meter directly into the thermal image – this enables you to document the load status directly in the thermal image when checking switching cabinets, for example, and to reliably assess the condition of the system

- Intuitive operation via touchscreen and joystick

Further advantages for building energy consultants

- Produce a professional report quickly and easily: The report wizard guides you step by step through the report creation process using stored standard templates. Or you can use the report designer to create customized templates

- Clever: The humidity mode visualizes the risk of mould at thermal weak spots directly in the thermal image using traffic light colours (red, yellow, green)

- Smart: Thermography and live streaming – with the testo Thermography App, your customer can conveniently follow the measurement on a smartphone/tablet

- Networked: Wireless transmission of readings from the optional humidity probe live in humidity mode – your values are always up to date, e.g. when you change rooms

- Flexible: Interchangeable lenses and manual focus for sharper images and more accurate results from different distances