- Home

- Set with flue gas analyzer testo 320 (with H2-compensated C...

Set with flue gas analyzer testo 320 (with H2-compensated C...

0563 3220 77

Set with flue gas analyzer testo 320 (with H2-compensated C...

0563 3220 77General technical data

| Weight | 573 g |

|---|---|

| Dimensions | 240 x 85 x 65 mm |

| Operating temperature | -5 to +45 °C |

| Display size | 240 x 320 pixels |

| Display function | Colour graphic display |

| Power supply | Battery: 3.7 V / 2,400 mAh; Mains unit: 6 V / 1.2 A |

| Maximum memory | 500 Measurement values |

| Storage temperature | -20 to +50 °C |

Differential Pressure - Piezoresistive

| Measuring range | ±10000 Pa |

|---|---|

| Accuracy | ±3 % of mv (10 to 10000 Pa) plus ±1 Digit ±0.3 Pa (0 to 9.99 Pa) plus ±1 Digit |

Flue gas O₂

| Measuring range | 0 to 21 Vol.% |

|---|---|

| Accuracy | ±0.2 Vol.% |

| Resolution | 0.1 Vol.% |

| Reaction time t₉₀ | < 20 s |

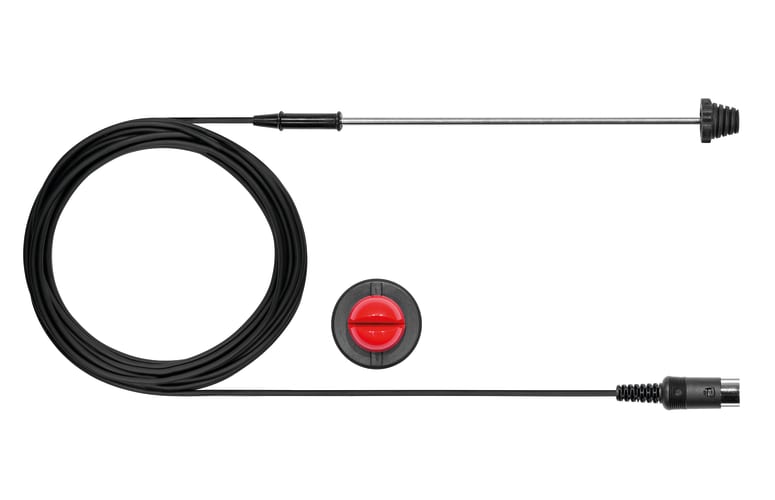

Accessories for probes

0554 1203

0554 1208

0600 9740

0600 9741

0600 9760

0604 0194

0554 0040

0554 3385

Combustion air / temperature

0600 9791

0600 9797

0600 9787

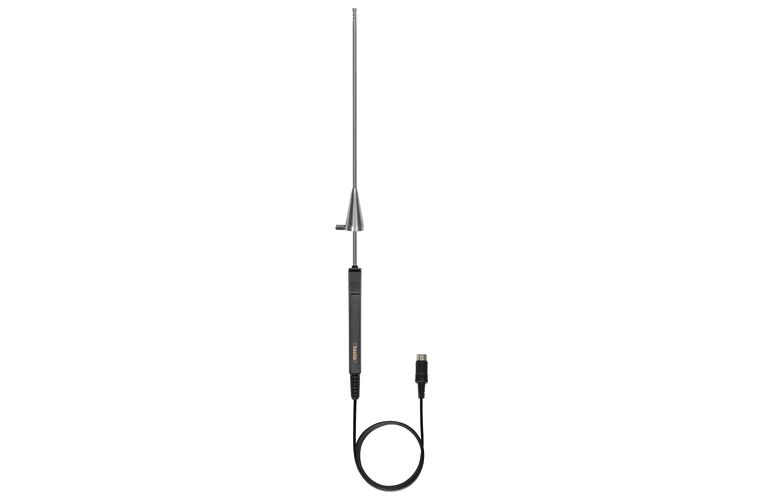

Probes

0600 9761

0600 9763

0600 9762

Temperature probes

0430 0143

0600 3692

Accessories for measuring instrument

0516 3300

0554 0040

0554 0307

0554 0549

0554 0568

0554 1105

0554 3332

0554 3385

0393 0103

Ambient CO measurement in the heated environment

Carbon monoxide (CO) is a colourless, odourless and taste-free gas, but also poisonous. It is produced during the incomplete combustion of substances containing carbon (oil, gas, and solid fuels, etc.). If CO manages to get into the bloodstream through the lungs, it combines with haemoglobin thus preventing oxygen from being transported in the blood; this in turn will result in death through suffocation. This is why it is necessary to regularly check CO emissions at the combustion points of heating systems and the surroundings.

Measuring the flue gas parameters of the burner (CO, O2, and temperature, etc.)

The flue gas measurement for a heating system helps to establish the pollutants released with the flue gas (e.g. carbon monoxide CO or carbon dioxide CO2) and the heating energy lost with the warm flue gas. In some countries, flue gas measurement is a legal requirement. It primarily has two objectives:

- Ensuring the atmosphere is contaminated as little as possible by pollutants; and

- energy is used as efficiently as possible.

Stipulated pollutant quantities per flue gas volume and energy losses must never be exceeded. Measurement in terms of results required by law takes place during standard operation (every performance primarily using the appliance). Using a Lambda probe (single hole or multi-hole probe), the measurement is taken at the centre of flow in the connecting pipe (in the centre of the pipe cross-section, not at the edge) between the boiler and chimney/flue. The measured values are recorded by the flue gas analyzer and can be logged either for print out or transfer to a PC at a later stage.

Measurement is taken by the installer at commissioning, and if necessary four weeks later by the flue gas inspector/chimney sweep, and then at regular intervals by the authorised service engineer.

Measuring pressure on burners (nozzle pressure, gas flow pressure, etc.)

Standard readings taken during services of domestic heating systems include checking the gas pressure on the burners. This involves measuring the gas flow pressure and gas resting pressure. The flow pressure, also called supplied pressure, refers to the gas pressure of the flowing gas and resting pressure of the static gas. If the flow pressure for gas boilers is slightly outside the 18 to 25 mbar range, adjustments must not be made and the boiler must not be put into operation. If put into operation nonetheless, the burner will not be able to function properly, and explosions will occur when setting the flame and ultimately malfunctions; the burner will therefore fail and the heating system will shut down.

Measuring temperatures on radiators

When measuring the temperature on radiators, the flow and return temperatures are recorded in particular and assessed by the tradesman. The flow temperature is defined as the temperature of a thermal transfer medium (e.g. water) that the system is supplied with. The temperature of the medium flowing out of the system is accordingly called the return temperature. To prevent losses within the heat distribution system and achieve a better level of efficiency in modern, heating technology, spot recording of flow and return temperatures is necessary at certain radiator pipes or screw fittings. Implementation of relevant measures ultimately leads to hydraulic adjustment on the basis of knowledge about the flow and return temperatures. This defines a procedure with which every radiator or heating circuit of a flat radiator within a heating system is supplied at a set flow temperature with the precise amount of heat needed to achieve the ambient temperature required for the individual rooms. Flawed operating conditions will result in considerable excess consumption of electricity and heating energy.

- Product brochure testo 320(pdf, 1.04 MB)

- Instruction manual testo 320(pdf, 2.56 MB)

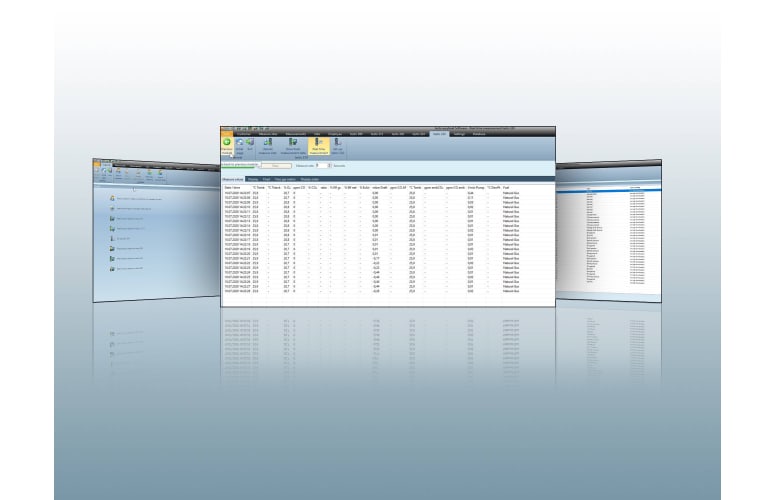

- Instruction manual EasyHeat software(pdf, 3.55 MB)

- Download testo 320 firmware(V1.12, 12.77 MB)If the firmware update does not start under Windows 8.1 or Windows 10, a new bootloader must be installed on the measuring device once.

A description and all necessary files can be found under the search term: Update-Kit / Bootloader - Testo ZIV driver ZIV 2000 for testo 320 and testo 330(v2.1, 2.22 MB)Testo ZIV driver in the 2000 version. The Testo ZIV driver is used to connect the testo 320 and testo 330 measuring instruments to an application program (sweeping district administration program) according to the interface Version 2.0 defined by the Zentralverband des Schornsteinfegerhandwerks (Central Association of Chimney Sweeps, ZIV). Please check with the manufacturer of your application program as to whether this interface is supported. If Microsoft .NET Framework 4.0 has not been installed on the computer, it must be downloaded from the Microsoft website and installed on the system.

- Testo ZIV driver for testo 300, testo 320 and testo 330(v2.3, 64.11 MB)The Testo ZIV driver is used to connect the testo 300, testo 320 and testo 330 measuring instruments to an application program (sweeping district administration program) according to the interface defined by the Zentralverband des Schornsteinfegerhandwerks (ZIV, Central Association of Chimney Sweeps) in version 1.0 of 01. August 2012, in version 2.0 of 13. February 2017 as well as version 3.0 from 02. July 2021. Please check with the manufacturer of your application program as to whether this interface is supported.

- testo 320 Bootloader(v1.18, 384.0 kB)

- Manual firmware testo 320(pdf, 47.3 kB)

- Update-Kit / Bootloader(V1.22, 1.24 MB)(testo 330 LL | testo 330i | testo 350 Control Unit + Analysis Box | testo 320)

If the firmware update does not start under Windows 8.1 or Windows 10, a new bootloader must be installed on the measuring device once.