Areas of use for the testo 882 infrared camera

Quality control in the building sector and water damage restoration, maintenance of mechanical and electrical installations, precise high-temperature measurements, prevention of mold, energy advice. The testo 882 infrared camera has all the features you need to carry out a wide range of different thermal imaging tasks.The impressive details of the testo 882 thermal imaging camera

- 76 800 temperature measuring points for precise thermal imaging and crisp, clear images: Infrared resolution 320 x 240 pixels, thermal image quality enhanced to 640 x 480 pixels thanks to SuperResolution technology

- Thermal sensitivity < 50 mK for measuring even the smallest temperature differences

- 32° lens for quick ‘n easy coverage of larger image sections, can be focused manually or with motor

- Automatic hot/cold spot recognition for instant critical temperature depiction

- Built-in digital camera with power LEDs for parallel real and thermal images

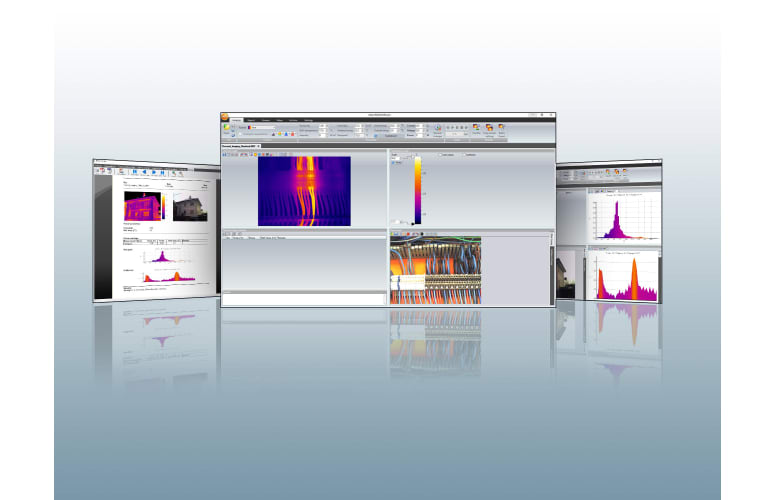

- Free IRSoft PC software for professional analysis of thermal images. TwinPix technology for overlapping images on your PC monitor. Ideal for allocating thermal images, documenting results and for planning further measures

- Voice annotations via headset

- Intuitive, one-handed operation for quick ‘n easy thermal imaging

Special measuring modes for even more precise thermal imaging

Special measuring modes and functions broaden your measuring spectrum and provide even more precise measurements for faster results:- Solar mode for identifying faults at photovoltaic systems: enter the externally measured radiation intensity of the sun at the point in time at which the image was taken into the camera. This value is saved alongside each of the thermal images to allow correct comparisons to be made

- Special measuring mode for detecting places where there is a risk of mold: the infrared camera can use the externally measured ambient temperature and humidity and the surface temperature to calculate the moisture value of each measuring point and depict it as a real moisture image

- High temperature option: the measuring range can be increased to 550 °C for even more flexibility