- Home

- testo 174 T zestaw startowy

testo 174 T zestaw startowy

0563 0561

testo 174 T zestaw startowy

0563 0561pamięć wewnętrzna do 16 000 odczytów, ok. 500 dni pracy baterii

Skład zestawu: 3 szt. mini rejestratora testo 174T z uchwytem ściennym, bateriami (CR2032 litowe) oraz fabrycznym protokołem kalibracji oraz interfejsu USB.

Stopień ochrony IP65, zgodny z HACCP, EN 12830

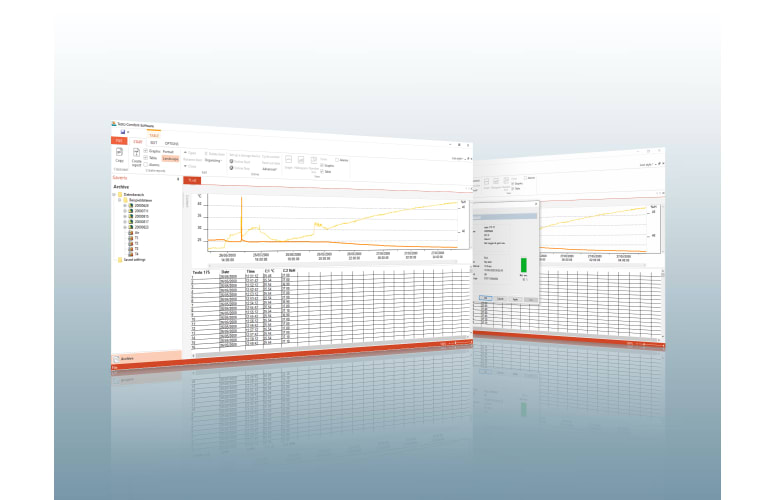

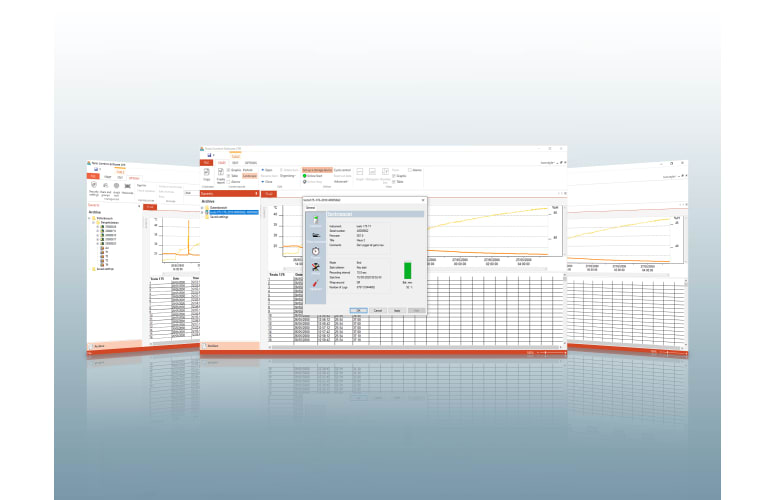

różne warianty oprogramowania do analizy danych

Produkt nie jest już dostępny. Czy znają Państwo już kolejny model?

Warto skorzystać z jego zalet: >> Do produktu

Warto skorzystać z jego zalet: >> Do produktu

3 szt. mini rejestratora testo 174T z uchwytem ściennym, bateriami (CR2032 litowe) oraz fabrycznym protokołem kalibracji oraz interfejsu USB.

Ogólne dane techniczne

| Waga | 35 g |

|---|---|

| Wymiary | 60 x 38 x 18,5 mm |

| Temperatura pracy | -30 do 70 °C |

| Materiał obudowy | Plastik |

| Klasa zabezpieczenia | IP65 |

| Kanały | 1 wewnętrzna |

| Kolor produktu | biały |

| Standardy | EU-dyrektywa 2014/30/EU; 2011/65/EU |

| Szybkość pomiaru | 1 min - 24 h |

| Typ baterii | 2 x bateria guzikowa (3 V, CR 2032) |

| Żywotność baterii | 500 dni (przy kroku pomiarowym 15 min.) |

| Pamięć | 16 000 mierzone wartości |

| Temperatura składowania | -40 do +70 °C |

Pomiar temperatury - NTC

| Zakres pomiarowy | -30 do +70 °C |

|---|---|

| Dokładność | ±0,5 °C (-30 do +70 °C) |

| Rozdzielczość | 0,1 °C |

Ogólne dane techniczne

| Materiał obudowy | Plastik |

|---|---|

| Kolor produktu | biały |

| Waga | 150 g |

Ogólne dane techniczne

| Wymagania systemowe | Windows 10; Windows® 11 ; others on request |

|---|---|

Zestawy produktowe

Zestawy produktowe

Niezawodny pomiar temperatury do monitorowania łańcucha chłodniczego i produktów wrażliwych

:

0572 0561

0572 0561

Akcesoria

Akcesoria

Bateria, typ CR 2032

:

0515 0028

0515 0028

Akcesoria

Profesjonalne oprogramowanie ComSoft do programowania i odczytu rejestratorów danych Testo oraz archiwizowania danych

:

0554 1704

0554 1704

Akcesoria

Oprogramowanie ComSoft 21 CFR Part 11 - nadające się do walidacji oprogramowanie do programowania i odczytu rejestratorów danych Testo oraz archiwizowania danych

:

0554 1705

0554 1705

Akcesoria

Interfejs USB do rejestratorów danych

:

0572 0500

0572 0500

Akcesoria

ComSoft Basic — oprogramowanie do programowania i odczytu rejestratorów Testo

:

0572 0580

0572 0580

Monitorowanie i dokumentowanie temperatury w chłodniach

Wiele produktów spożywczych lub farmaceutycznych musi być przechowywanych w określonym zakresie temperatur. Może się to odbywać w pojedynczych chłodniach, ale także w specjalistycznych magazynach chłodniczych lub magazynach wysokiego składowania. We wszystkich tych obiektach chłodniczych temperatura musi być stale dokumentowana, ponieważ zarówno w przemyśle spożywczym, jak i farmaceutycznym obowiązują surowe przepisy dotyczące zarządzania jakością.

Rejestratory są zazwyczaj umieszczane w "krytycznych punktach kontrolnych" (CCP) w chłodni, aby umożliwić wykrycie wszelkich wahań temperatury i podjęcie odpowiednich działań. Krytyczne miejsca obejmują drzwi lub przejścia do innych stref temperaturowych w magazynie.

Rejestratory są zazwyczaj umieszczane w "krytycznych punktach kontrolnych" (CCP) w chłodni, aby umożliwić wykrycie wszelkich wahań temperatury i podjęcie odpowiednich działań. Krytyczne miejsca obejmują drzwi lub przejścia do innych stref temperaturowych w magazynie.

Monitorowanie i dokumentowanie temperatury transportu

Podczas transportu żywności i farmaceutyków w większości przypadków muszą być przestrzegane jasno określone limity temperatury - i to w sposób ciągły i bezproblemowy. Niewłaściwe warunki temperaturowe podczas transportu mogą powodować poważne straty jakości lub nawet całkowitą utratę wartości monitorowanych produktów.

Za pomocą rejestratora danych można monitorować towary w transporcie, aby upewnić się, że przestrzegane są określone strefy temperaturowe; dane te można następnie odczytać, przeanalizować i zapisać za pomocą specjalnego oprogramowania.

Za pomocą rejestratora danych można monitorować towary w transporcie, aby upewnić się, że przestrzegane są określone strefy temperaturowe; dane te można następnie odczytać, przeanalizować i zapisać za pomocą specjalnego oprogramowania.

Monitorowanie temperatury w pomieszczeniach do przechowywania żywności w stanie głębokiego zamrożenia

Istnieje wiele obiektów, w których należy przechowywać (głęboko) mrożonki. Obejmują one indywidualne mroźnie u małych producentów żywności (np. sklepy mięsne), restauracje i supermarkety, mroźnie w przemyśle spożywczym, aż po specjalistyczne chłodnie/magazyny mroźnicze wysokiego składowania. We wszystkich tych obiektach temperatura musi być stale dokumentowana. W Europie wolno używać wyłącznie urządzeń rejestrujących temperaturę zgodnych z normą EN 12830.

Rejestratory danych są zwykle używane do pomiaru temperatury powietrza w tego rodzaju obiektach magazynowych. Urządzenie pomiarowe umieszczane jest w mroźni w miejscach krytycznych, o ile to możliwe, takich jak drzwi lub agregaty chłodnicze, gdzie rejestruje dane dotyczące temperatury w określonych odstępach czasu (zazwyczaj: co 15 minut). Zarejestrowane dane mogą być następnie analizowane i archiwizowane przy użyciu specjalnego oprogramowania.

Rejestratory danych są zwykle używane do pomiaru temperatury powietrza w tego rodzaju obiektach magazynowych. Urządzenie pomiarowe umieszczane jest w mroźni w miejscach krytycznych, o ile to możliwe, takich jak drzwi lub agregaty chłodnicze, gdzie rejestruje dane dotyczące temperatury w określonych odstępach czasu (zazwyczaj: co 15 minut). Zarejestrowane dane mogą być następnie analizowane i archiwizowane przy użyciu specjalnego oprogramowania.

- Zestaw startowy testo 174 T - ulotka(pdf, 1.76 MB)

- EU declaration of conformity testo 174 T(pdf, 33.8 kB)

- Short manual testo 174(pdf, 760.31 kB)

- Instrukcja obsługi testo 174(pdf, 2.1 MB)

- Short manual testo 174-H. -T(pdf, 1.94 MB)

- testo usb driver - Instruction manual(pdf, 676.7 kB)

- Instrukcja obsługi - oprogramowanie ComSoft Basic(pdf, 1.2 MB)

- testo usb driver - for various measuring instruments(v2.9.1, 2.02 MB)USB driver for the following devices with USB port: * USB Interface testo 174 / 177 - T + H * testo 300 / 320 / 330 / 330i / 335 / 340 / 350 * testo 435 * testo 556 / 560 / 570 / 580 * testo 635 * testo 735 * testo 845

- testo usb driver - Instruction manual(pdf, 676.7 kB)

- Instrukcja obsługi - oprogramowanie ComSoft Basic(pdf, 1.2 MB)

- testo usb driver - for various measuring instruments(v2.9.1, 2.02 MB)USB driver for the following devices with USB port: * USB Interface testo 174 / 177 - T + H * testo 300 / 320 / 330 / 330i / 335 / 340 / 350 * testo 435 * testo 556 / 560 / 570 / 580 * testo 635 * testo 735 * testo 845

- Instrukcja obsługi - oprogramowanie ComSoft Basic(pdf, 1.2 MB)