- Home

- testo 340

testo 340 - Industrial Flue Gas Analyser (SO2 Kit)

0563 9351

testo 340 - Industrial Flue Gas Analyser (SO2 Kit)

0563 9351Designed to withstand industrial demands, the testo 340 offers an extended measurement range, allowing for accurate readings even in high-concentration gas environments. The automatic sensor protection system prevents overloads and ensures continuous operation without interruptions. Its precalibrated gas sensors enable quick replacements, reducing downtime and maintenance efforts.

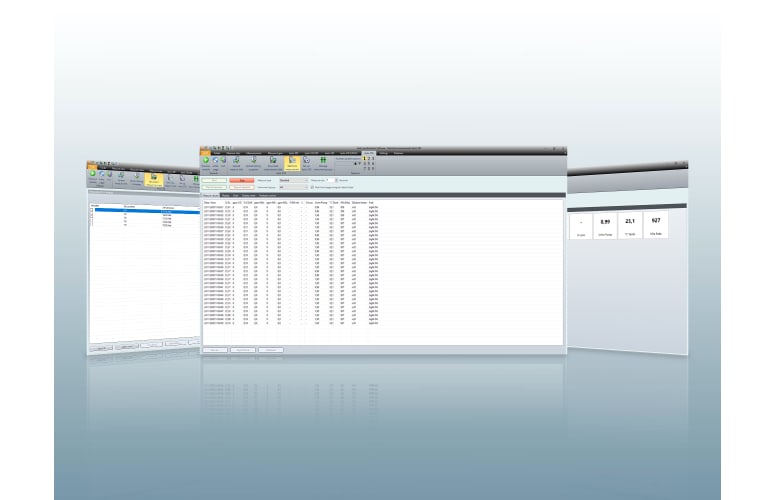

With seamless data management capabilities, users can transfer and analyse emissions data directly on a PC or notebook for detailed reporting and compliance tracking. Additionally, the measurement range of CO, NO, NOlow, and SO2 sensors can be increased by a factor of five, ensuring flexibility across different industrial applications.

(Note: The sampling probe is sold separately and must be selected based on the application.)

For leasing options and additional accessories, contact us today.

General technical data

| Weight | 960 g |

|---|---|

| Dimensions | 283 x 103 x 65 mm |

| Operating temperature | -5 to +50 °C |

| Product-/housing material | TPE PC |

| Protection class | IP40 |

| Connectable probes | 1 x flue gas probe; 1 x temperature probe; 1 x differential pressure |

| Product colour | Black |

| Battery life | > 6h (Pumpe an, Displaybeleuchtung aus, bei 20°C) |

| Display type | graphic Display |

| Display size | 160 x 240 pixels |

| Display function | Graphic display |

| Power supply | Battery block 3.7 V / 2.4 Ah, Mains unit 6.3 V / 2 A |

| User defined fuels | 10 user-defined fuels incl. test gas as fuel |

| Pump flow | 0.6 l/min (regulated) |

| Hose length | max. 7.8 m (corresponds to two probe hose extensions) |

| Max. pos. press./flue gas | 50 mbar |

| Max. neg. press./flue gas | -200 mbar |

| Maximum memory | 100 folders |

| Storage per folder | Max. 10 sites |

| Storage per site | Max. 200 logs |

| Miscellaneous | The max. number of logs is determined by the number of folders or sites |

| Interface | Bluetooth®; USB; IR/IRDA interface; gas outlet; Mains connection; probe input/ probe inputs; Differential Pressure |

| Storage temperature | -20 to +50 °C |

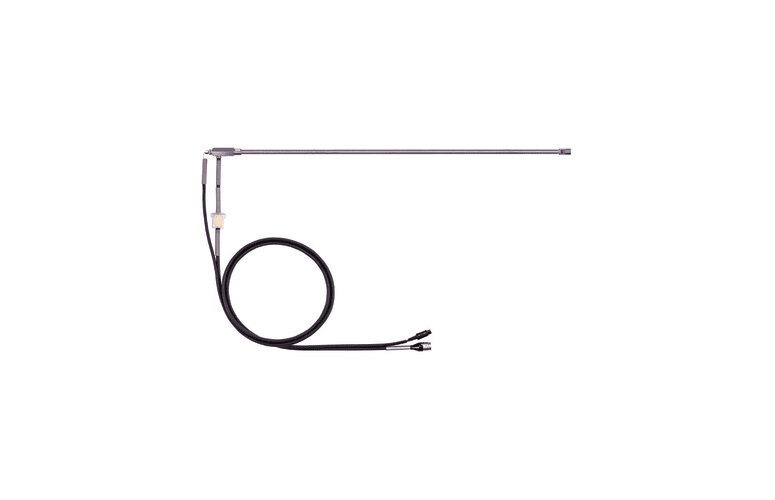

Flue gas probes

0600 9767

0600 9766

0600 8764

0600 8765

0600 8766

0600 8767

0600 7610

0600 7555

0600 7556

Pitot tubes

0635 2145

0635 2345

Temperature probes

0600 9797

Accessories

0554 1202

0554 0549

0554 1096

0554 3334

0554 1103

Analysis of the gas atmosphere (thermal processes)

Flue gas analysis is used for thermal manufacturing processes, from ongoing emission control, via setting and optimisation of combustion systems, through to process monitoring. Flue gas analysis instruments serve to optimise operations and save fuel. At the same time, flue gas measurement enables checking and monitoring of flue gas emission limit values laid down by the authorities, along with functional testing of permanently installed emission instruments. Flue gas analysis instruments are increasingly used for monitoring process and product quality.

Advantages of the testo 340

Ideal for measurements at high concentrations

- When recording extremely high concentrations, the measuring range extension is automatically activated. This enables continuation of the measurement. The gas sensor is not subjected to any higher stress than it is at low gas concentrations. This ensures the sensor has the longest possible service life.

Service measurement on industrial engines

Flue gas analysis instruments are one of the items of equipment that are used on a daily basis by service engineers to achieve optimum tuning of engines. Flue gas measurement is used on industrial engines when they are commissioned, at regular maintenance intervals or for troubleshooting when they are running in an unstable way. The background to flue gas measurement is tuning the engine to the optimum operating parameters while complying with the limit value regulations in force. Maintenance work that is carried out regularly makes an important contribution to avoiding downtimes over the long term, to ensuring the quality of the system and thus a high level of efficiency and to having a significant influence on emission levels.

Advantages of the testo 340

Separate NO and NO2 measurement

- The real NOx value is measured with the NO and NO2 sensor combination. In gas engines, the NO2 component of the NOx value can fluctuate greatly, so the separate measurement of each of the gases is necessary for correct NOx values.

Measurements even at high CO concentrations

- At unexpectedly high concentrations (up to 50,000 ppm), the automatic dilution of the sensor with fresh air allows measurements even when the engine conditions are not defined, without negatively affecting the service life of the sensor.

Special flue gas probes for industrial engines as an accessory

- These probes are highly heat-resistant and specially designed to compensate for different pressure conditions, e. g. for measurements before and after the catalytic converter.

Engine-specific parameters

- The most important parameters for industrial engines such as O2, CO, NO, NO2, NOx and Lambda can be displayed simultaneously.

Service measurement on industrial burners

The testo 340 flue gas analysis instrument offers service engineers a vast range of technical functions. In addition to compliance with environmental regulations, it can also be used to check correct functioning and to optimise burner efficiency. Flue gas measurement is used on industrial burners for safe and efficient commissioning, at regular maintenance intervals or for troubleshooting when they are running in an unstable way.

Advantages of the testo 340

Time saving through helpful instrument pre-settings

- Typical fuels, a sensible sequence of flue gas parameters in the display and useful instrument settings are preset for each application. Tips on the display take the user through the measurement (no prior knowledge specific to the instrument needed). The testo 340 is ready for operation within just a few minutes.

Unrestricted measuring at high concentrations

- When commissioning burners or carrying out measurements on unfamiliar systems, very high concentrations can occur unexpectedly. The measuring range extension is automatically activated in such cases.

Always ready for use – even in tough day-to-day work

- The robust housing protects the measuring instrument from knocks.

- Datasheet testo 340(pdf, 407.83 kB)

- Instruction manual testo 340(pdf, 1.25 MB)

- Approval and Certification testo 340(pdf, 141.84 kB)

- Instruction manual easyEmission(pdf, 2.36 MB)

- testo 340 Firmware update(V1.21, 3.61 MB)

- testo usb driver - for various measuring instruments(v2.9.1, 2.02 MB)USB driver for the following devices with USB port: * USB Interface testo 174 / 177 - T + H * testo 300 / 320 / 330 / 330i / 335 / 340 / 350 * testo 435 * testo 556 / 560 / 570 / 580 * testo 635 * testo 735 * testo 845