The Control Unit controls the analyzer box and displays the measurements in a high definition graphic display. Select the “Turbine” icon and the analyzer will activate the proper settings and guide you through the measurement. View the separate values or switch to the trending line graphs. Save each reading or let the automatic program data log the test runs.

The Control Unit’s magnets allow you to dock in the control room and with Bluetooth connectivity (to over 330 feet) allows you to see the measurements and make easier and faster control adjustments. Stream the measurements to the PC connected via USB while the Control Unit wirelessly displays measurements at a different location.

The Analyzer Box contains the gas path, sensors, pumps, chiller, power, etc. Wireless capability allows for a short sample line (transmit data via Bluetooth) which results in sensor response times faster than any other portable analyzer in the market. The analyzer gas path (is designed conceptually like a circuit board) is non-reactive to NO2, SO2 or other acid gas and it’s nearly indestructible. The moisture in the exhaust gas is condensed and removed with the integrated temperature-controlled Peltier sample condition system.

The sampling pump and hose configuration are engineered for the highest accuracy. The pump pulls a high velocity sample through a Teflon line while monitoring and automatically adjusting to maintain a constant sample flow rate. This eliminates measurement drift associated with: particulate filter loading, high draft, or fluctuating in-stack pressures. It’s the most advanced and most powerful sample system in the market. The system satisfies EPA compliance for a dry sample and also protects the sensors for longer life.

Testo’s sensors are unique. We pioneered and have developed our own designs which result in extraordinary calibration stability and life span. Integrated circuit boards allow for pre-calibrated, plug & play sensor swapping. The circuit boards monitor individual sensor temperature, signal output, and other sensor characteristics resulting in stable and repeatable measurements. Linear output is critical for calculating mass emissions especially in the higher O2 (14-16%) ranges. Testo’s sensors deliver linear results.

Communications & Software Connectivity is abundant with either easyEmission software (0554 3334) for everyday testing and data logging or TECsoft software (400563 3511) for compliance testing. Other digital options include an analog output box, and an SDK (toolbox).

Ideal features for turbine testing

- Sensors include: Low NOx (NO low 0.0 ppm - 300.0 ppm, NO2 0.0 ppm - 500.0 ppm), CO low (0.0 ppm – 500.0 ppm with stepped dilution factors to 40x), and high resolution O2 (0.00 – 25.00%).

- Integrated dilution system to expand testing range and protect sensors. Single Slot for the CO sensor or switch to “overall-dilution” to double the range on CO, NO, and NO2. The analyzer will automatically calculate and display the corrected values. The dilution system will extend sensor life and still maintain accurate measurements.

- The Control Unit can simultaneous show multi-unit parameters. See the raw NOx and CO readings along with the O2 corrected NOx and CO values at 15%.

- Automatic data logging programs – Set up one run or three. Set the time interval and sampling rate. During the run, check the calculated averages NOx and CO reading against your permit limits. This saves valuable time and allows you to stop a test and adjust the engine instead of wasting time on a failed test.

- Convenient “fresh air” button purges sensors. Press the button to purge instead of climbing ladders to remove the probe. The “purge” increases sensor life, establishes better sensor equilibrium, and virtually eliminate measurement drift.

- Onboard diagnostics helps you before the emissions test! Push the i (information) button to see: sensor, battery, error code, and leak check status.

- On-Site Calibration – Test protocols require on site calibrations. The testo 350’s simple procedures and intelligent feedback lets you know if you’re having gas delivery or sensor problems. It shows the gas flow rate and even detects and informs you if the concentrations are not correct. The 350 has instrument intelligence at the highest level.

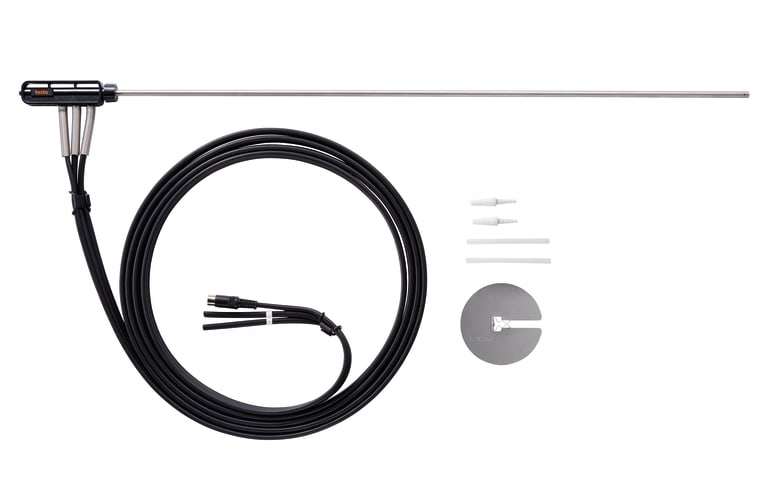

- The probe is made for high temperatures and has a heat deflector shield and cone allow it to be used on hot engine applications. A 13-foot Teflon lined hose and an extra filter/condensate trap.

Other useful options for Turbine Testing:

- Hose extensions -9-foot quick connect extensions means you can extend the hose with 3 extensions to 53 feet and still maintain proper flow rate. Disconnect them for easier, less bulky transport.

- Longer 28 inch “snap in” probe shaft.

Two Software Options:

- easyEmissions – standard software that allows for real-time testing with tabular, graphic and block displays, downloading from the analyzer as PDF or into excel and complete analyzer control.

- TECsoft (Testing & Emission Compliance Software) – real time data logging (or downloading from instrument memory) directly into excel report templates. Highly flexible and easily customized excel report templates.

Probes and Hoses - Options

- Probe adapters to attached you own sampling hose via Swagelok fittings

- Industrial sample probes from 3 feet to 9 feet long. Made from stainless steel, Inconel, or ceramic will cover a wide variety of temperature needs. From 1112⁰F to 3200⁰F.

- Heated sample lines (self-regulating), lightweight with small turning radius and with temperature notifications LEDs lights inform you of heating status.