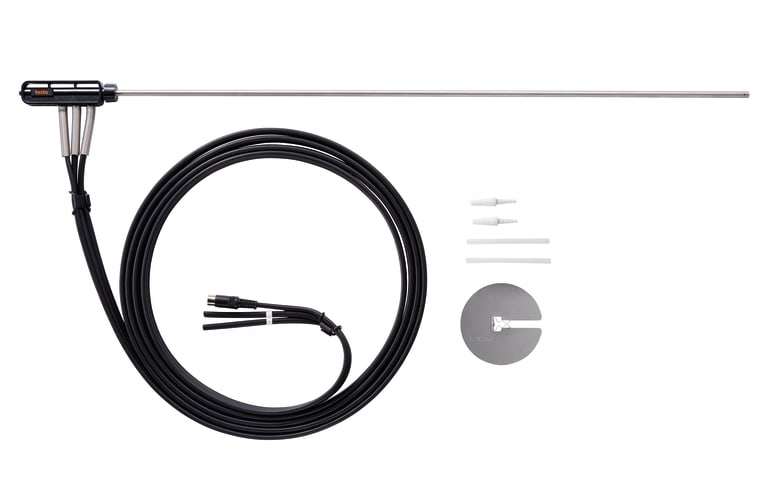

The testo 350 exhaust gas analyzer is made up of two separate units

- The testo 350 Control Unit is used to control emission measurements. It has a clearly structured graphic display, and four different menu applications to choose from, including burner / gas turbine / motors / user-defined applications. The instructions on the display guide you through the measurement and make the steps leading up to it easier. This saves both time and hassle. The Control Unit can also be used to control the Analysis Box when it is not at the exhaust gas pipe or measurement site. This is advisable when working on larger systems.

- The testo 350 Analysis Box contains the sensor system and electronics. It comes standard equipped with an O2 gas sensor. At least one more sensor (maximum of six) is needed to operate the Box. Optional sensors include sensors for CO, CO2, NO, NO2, SO2, H2S and CxHy.

The increased measuring range (thinning) allows you to carry out unlimited measurements with higher gas concentrations. It is automatically activated when gas concentrations are unexpectedly high. The measuring range of a selected sensor can be increased by a certain factor. An opening on the underside gives you access to the relevant service and wearing parts, such as pumps and filters. The testo 350 also has numerous diagnosis functions with easy to understand readings and information. The analyzer constantly displays the current reading.

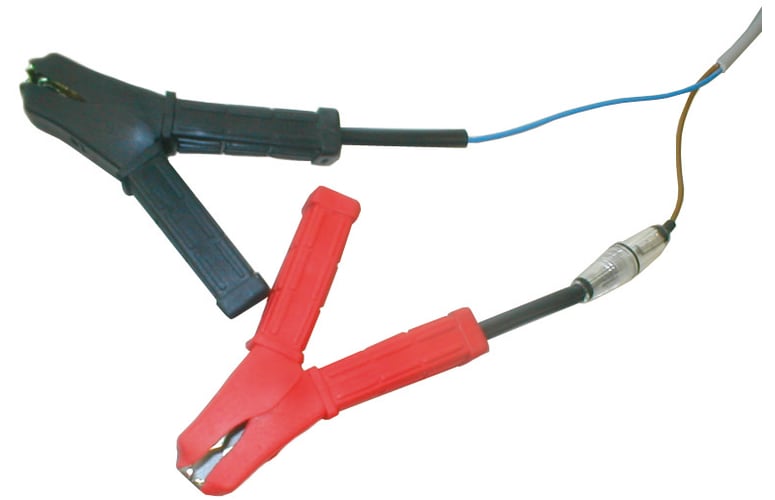

The Analysis Box can be controlled by the Control Unit or operated via USB, Bluetooth® 2.0, or CANCase from a PC or notebook. After the Analysis Box has been programmed, it can carry out measurements independently, save the results, and transfer the data to the Control Unit.

Conducting industrial emission measurements with the testo 350

The testo 350 exhaust gas analyzer has been specially designed for carrying out industrial emission measurements in the field. In the tab “Applications” you can find out more about:►Emission measurements on industrial motors

►Emission measurements on burners

►Emission measurements on gas turbines

►Emission measurements on thermo processes